Slitting Line Special & Optional Auxiliary Equipment

* Exchangeable slitter x 2 sets train type

* Ergonomic Slitter door to open sideways

* Turret for quick changing Slitting tools & Separators

* Hydraulic jaw to fix slitter tools in 5 seconds

* PU coated Tension Rolls for delicate surface materials

* Beltbridle TM Tensioner for delicate surface materials

* Turnstile – Cross type & I type

Almost all Slitting machine lines are custom-made, but there are some Special & Optional Auxiliary Equipment changes to satisfy our clients’ special requirement.

* Exchangeable slitter x 2 sets train type

1. Two slitters are exchangeable quickly.

2. While one slitter is on-line operating, the other one off-line can be prepared with slitting tools ready for next order.

3. Less machine downtime than changing slitting tools on line operation.

* Ergonomic Slitter door to open sideways

1. Door to open sideways is an ergonomic structure.

2. Operators use less muscle for changing slitting tools.

3. Less work fatigue and more safety for operators.

* Turret for quick changing Slitting tools & Separators

1. While machines are in operating, operator can prepare the slitting tools on tool turret off-line.

2. Slitting tools and separators can be changed quickly.

3. Less set-up time for slitting tools

4. Less machine downtime.

* Hydraulic jaw to fix slitter tools in 5 seconds

1. Hydraulic jaw can easily eliminate the gaps between knives and spacers and fix knife clearance.

2. In 5 seconds to get slitting tools setup ready.

* Tension pad with adjustable pressure in 7 sections

1. Coil thickness variation from center to edge may cause some strips loose tension on recoiling.

2. Tension pad in 7 sections with independent adjustable pressures can provide proper tension on those strips of different thickness in one coil.

* PU coated Tension Rolls for delicate surface materials

1. Steel rolls with PU coated can endure the strips burr cutting and last for long time.

2. PU layer with adequate softness and resilience is especially suitable for shining materials that demand no scratch on surface.

3. The PU roll can provide different variable pressures on each strip of which the thickness is in differential from edge to center in one coil.

4. Functions of PU roll are closed to Beltbridle TM Tensioner, but maintenance cost is much lower.

* Beltbridle TM Tensioner for delicate surface materials

1. Beltbridle TM Tensioner consists many independent belts with variable speed control on each separate belt.

2. Beltbridle TM Tensioner can provide speed differential on each strip of which the thickness is in differential from edge to center in one coil.

3. No scratch on shining material with delicate surface.

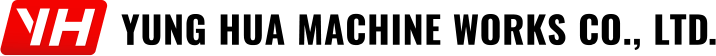

* Turnstile – Cross type & I type

1. Turnstile cross type or I type is offline standby storage bars for recoiled strip coils.

2. It can save machine downtime waiting for packing on line and crane lifting for load-out.

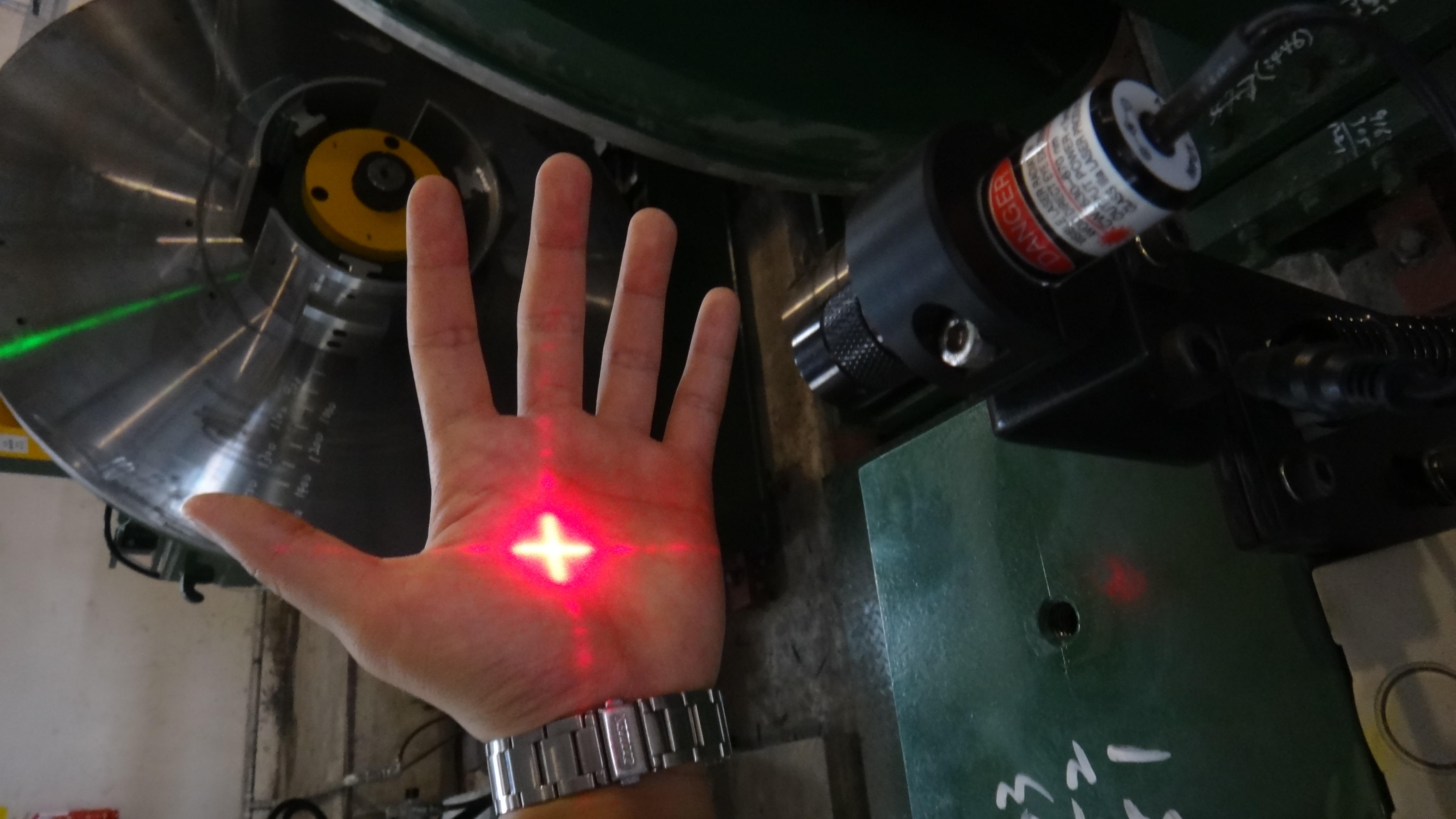

* Laser guide for coil to load on uncoiler

1. Laser beams mark the accurate position for coil car to adjust coil height and edge. Operator can follow the beam guidance to load coil on uncoiler mandrel accurately, easily, and quickly.