Safety

A Safety Machine is mainly verified to EN ISO 13849-1: PL e (Cat. 4) requirement in accordance with:

EN 60947-5-3, EN ISO 14119, EN 62061: SIL CL 3…etc.

Safety gate with sensors can provide the all-around protection and keep operators from any injury caused by the running machine during operation. Safety system includes not only basic mechanical safety protections, but also electrical double safety circuit control.

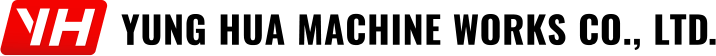

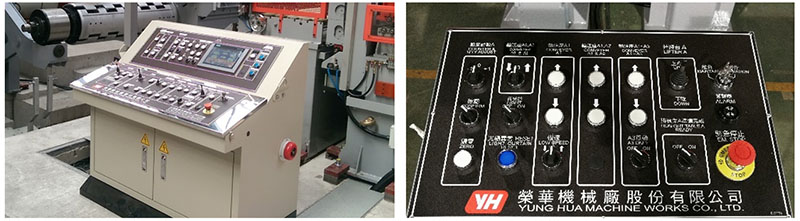

For Total Safety Oriented Operation, Three Operation Modes are available on control panel with key lock.

- Manual Mode feed/adjustment (Operator must operate with two hands + machine limited speed)

- Auto Run Mode (Operators stay in safe distance + machine can run max. speed)

- Maintenance Mode (Most electrical and hydraulic power are disabled and locked except specified maintenance function.)

CE safety machine requires to meet the main directives:

2014/30/UE Electromagnetic Compatibility

2006/42/EC Machinery Directive

2006/95/EC Low Voltage Directive

For different machines, different standards are requested, such as:

EN ISO 12100 :2010 Safety of machinery - General principles for design – Risk assessment and risk reduction

EN ISO 13849-1:2015 Safety of machinery - Safety-related parts of control systems -Part l: General principles for design

Our machines design meets required EN ISO standards, applicable for CE Safety Certification.

-

Safety Covers for moving parts is the basic when machine is running.

-

Mechanical Safety Pins together with Electrical Safety Sensors to lock the moving parts and deactivate the driver power when adjustment or maintenance is processing.

-

Emergency Stop not only on main operation panels, but also other accesses.

- Safety lock for maintenance engineer to secure their work in safe circumstances.

Laser Guides for Height and Edge are our auxiliary devices to help operator to load on coil easily by laser mark guidance. The devices are controlled by buttons on operation panel. This function is particularly useful for CE and EN ISO-13849-1 safety machines, of which the operator stay outside the fence in distance to load on coil.

Laser Height Guide can help operator follow the laser mark to align the coil height to top of mandrel.

Laser Edge Guide can help operator follow the laser mark to align coil at center of mandrel.

Two types, stop-to-cut type with guillotine shear or non-stop cutting type with rotary or flying shear. The differences are as below table.

|

ItemType |

Stop-to-cut |

Non-stop cutting |

|

Shear type |

Guillotine shear |

Rotary or flying shear |

|

Shear drive |

Hydraulic |

Servo motor |

|

Cutting process |

Feeding – stop – waiting shear to cut (one cycle) |

Non-stop feeding & shear tracking length to cut |

|

Material thickness |

0.2~ 25mmT |

0.2~ 4.5mmT |

|

Scratch on surface |

No scratch |

No scratch |

|

Roll mark on surface |

Depends on material |

No mark |

|

Critical required surface |

Not recommended |

Recommended |

|

Productivity |

As standard base |

About 2~5 times higher |

In short, the advantage of rotary shear and flying shear is faster production speed, no roller mark on material surface, and that of guillotine shear is cost lower.