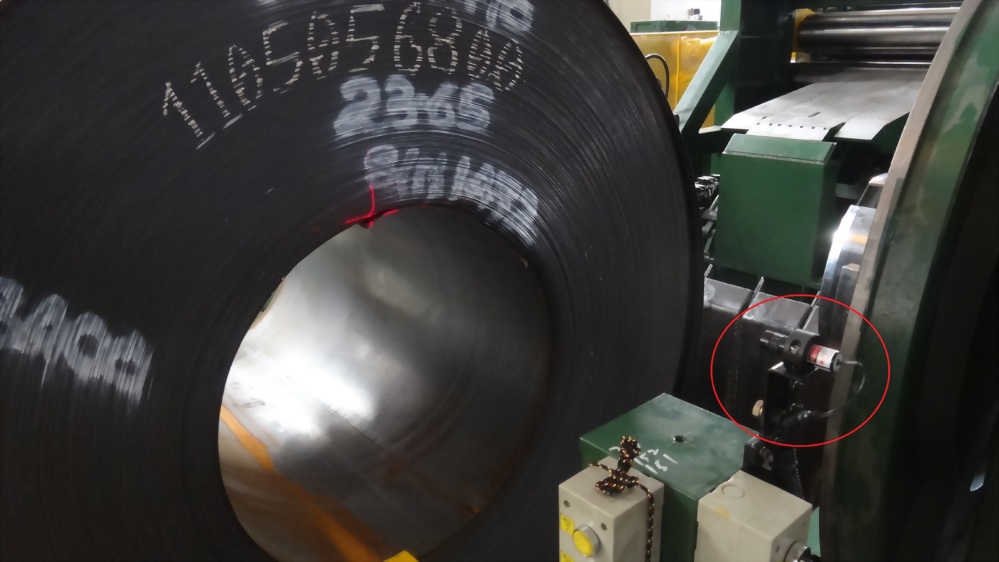

Cut-to-length line Special & Optional Auxiliary Equipment

*Precision Six-Hi double Cassette Leveler

* Laser guide for coil to load on uncoiler

*Laminator for paper or film

*Side trimmer

*Off-line scrap winder – Tension free

*On-line scrap winder speed & torque auto adjusted

*Paper rewinder

Almost all our cut-to-length machine lines are custom-made, but there is always some changes on Special & Optional Auxiliary Equipment to meet our clients’ special requirement.

Special & Optional Auxiliary Equipment:

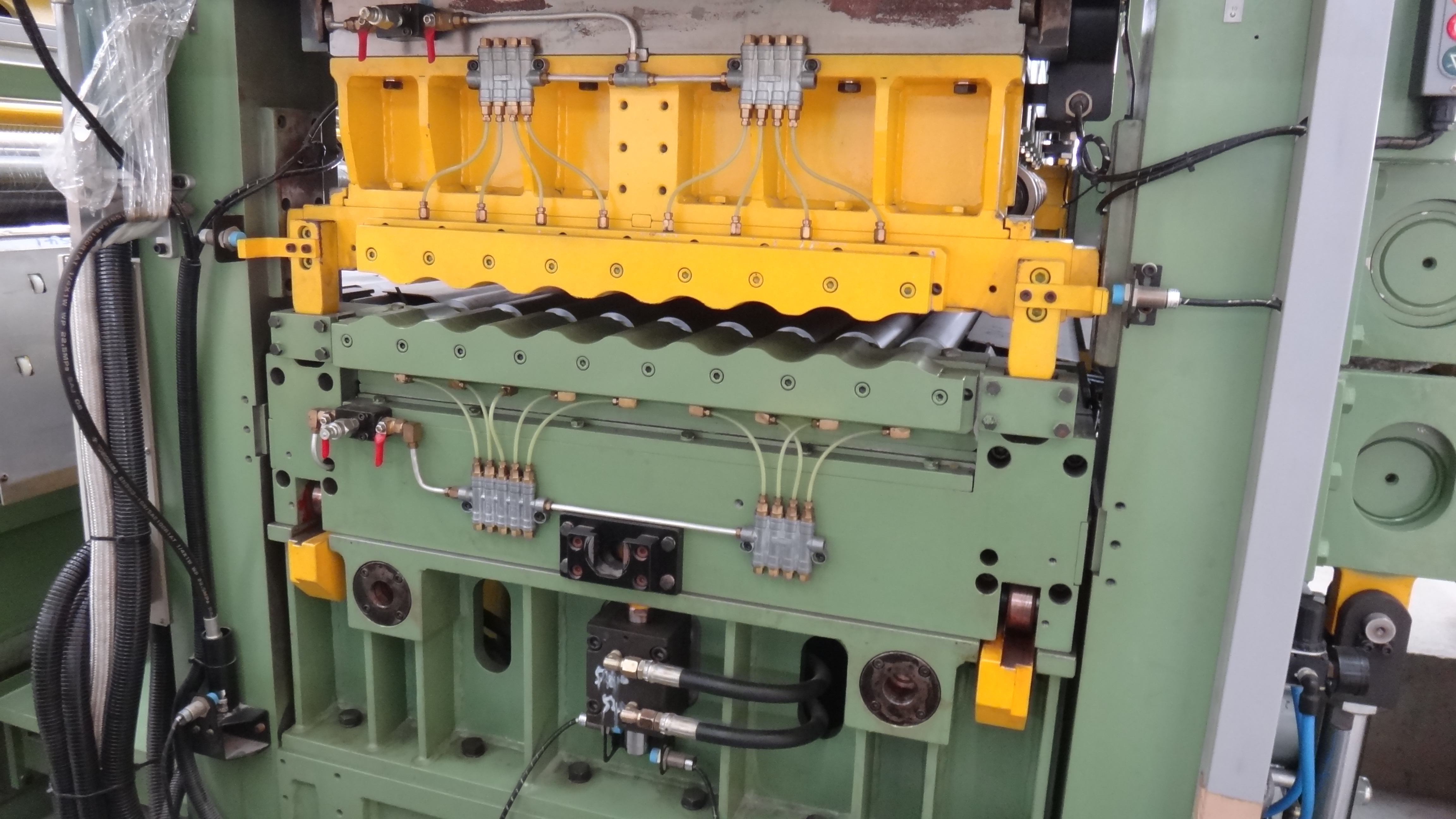

*Precision Six-Hi corrective leveler with adjustable backup rolls in separate control to eliminate “edge wave” and “center buckle”

1. Precision Six-Hi leveler with adjustable backup rolls is a more sophisticated leveler for coil width of 1250mm or 1550mm with five or seven precision backup rolls which are special designed device.

2. The height adjustment range of backup rolls is much larger than those made driven by slide wedge. Of course, the function is better.

3. With the skillful adjustment of different backup rolls height, operator can deflect work rolls according to the coil strip surface so to eliminate “edge waves” and “center buckles” and achieve the flatness as required.

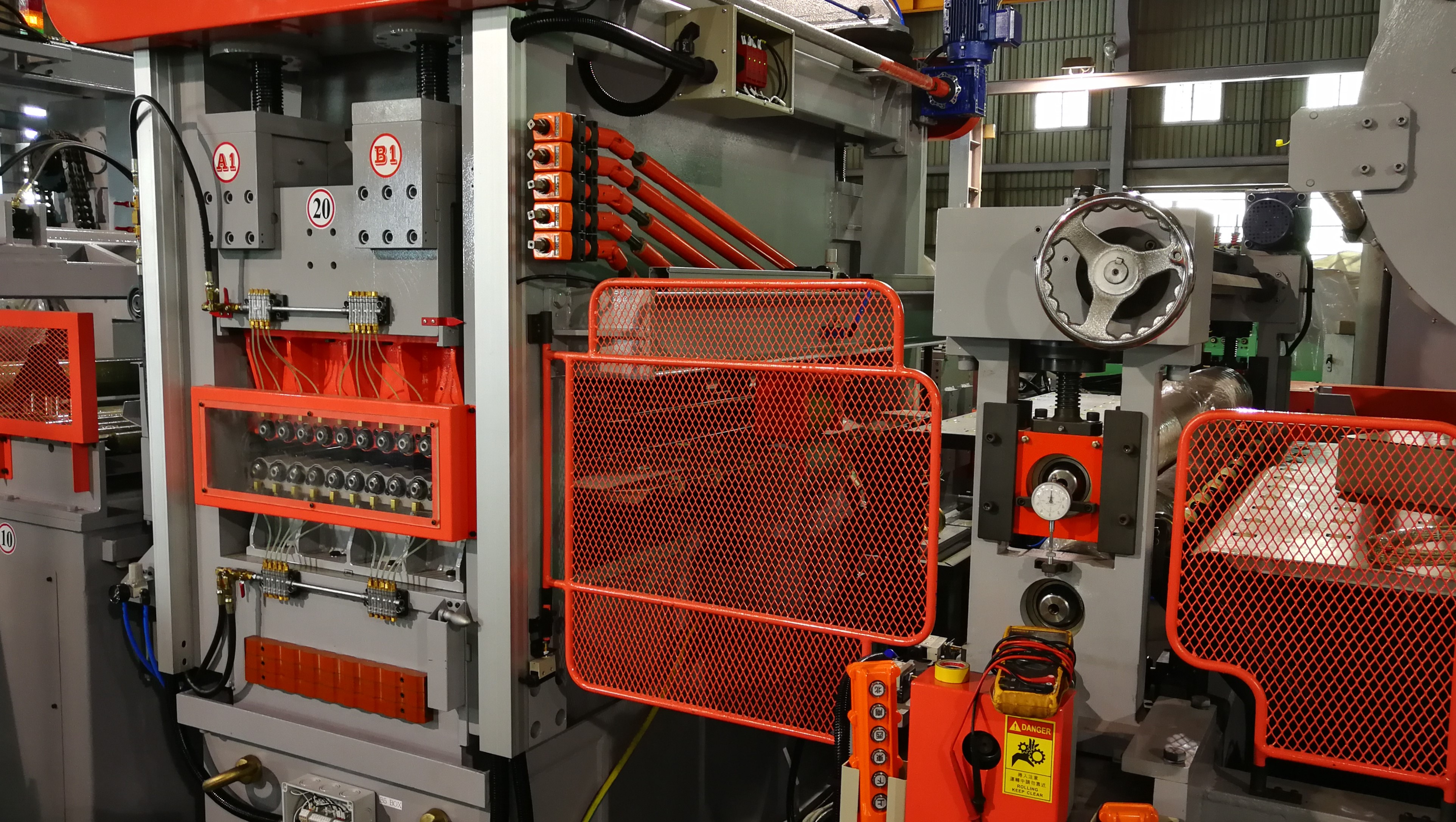

*Precision Six-Hi Double Cassette Leveler

1. Cassette leveler is basically equipped all the functions that above Precision Six-Hi corrective leveler with adjustable backup rolls can do.

2. Furthermore, cassette leveler is equipped with exchangeable cassettes of 2 sets different work rolls of diameter 50mm and 60mm for different material thickness and different surfaces.

3. When one cassette leveler is working on-line, the other off-line cassette can be easily opened for maintenance or cleaning.

4. The two cassette levelers can be exchanged ready for operation within 10 minutes through MHI touch screen intuitive guidance and control.

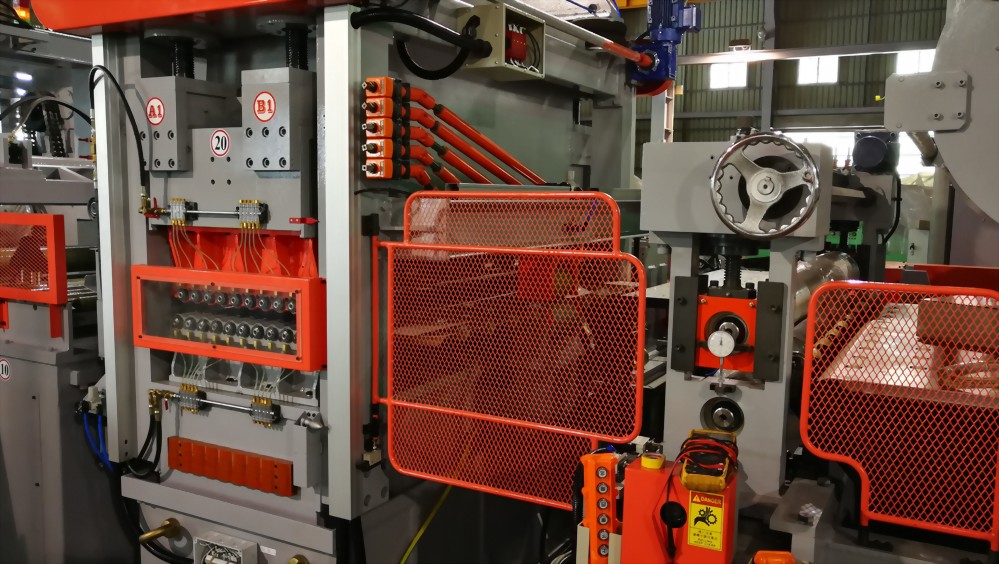

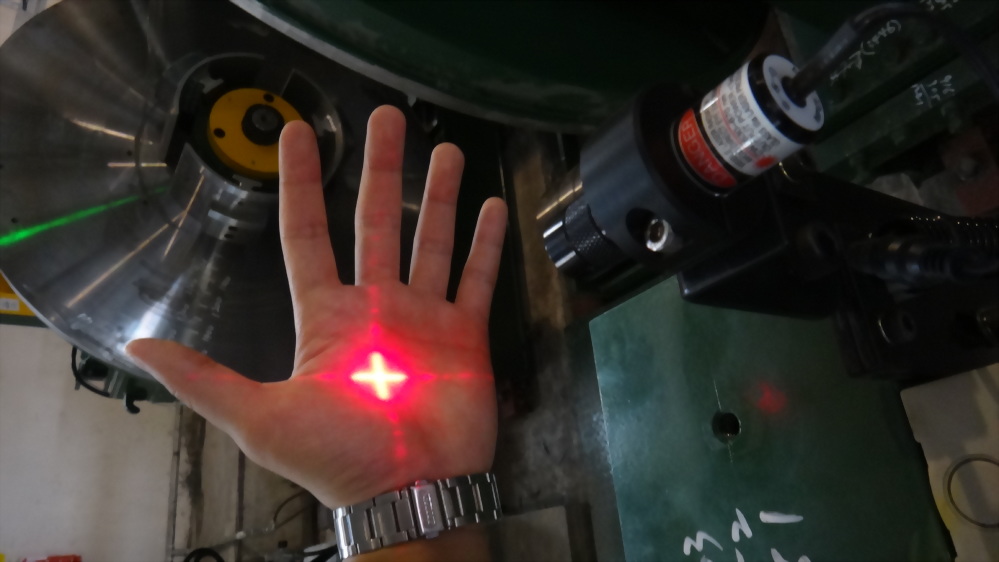

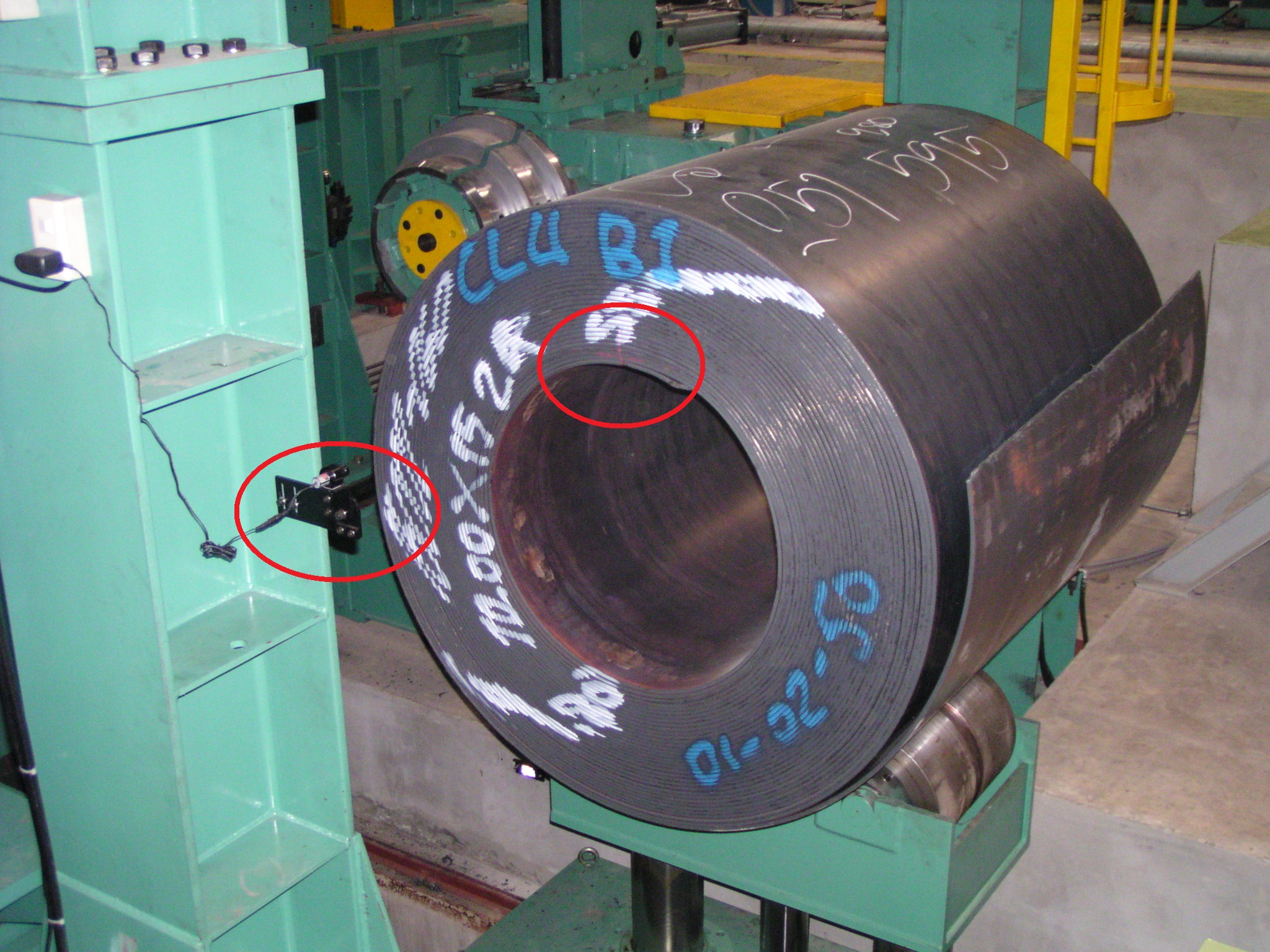

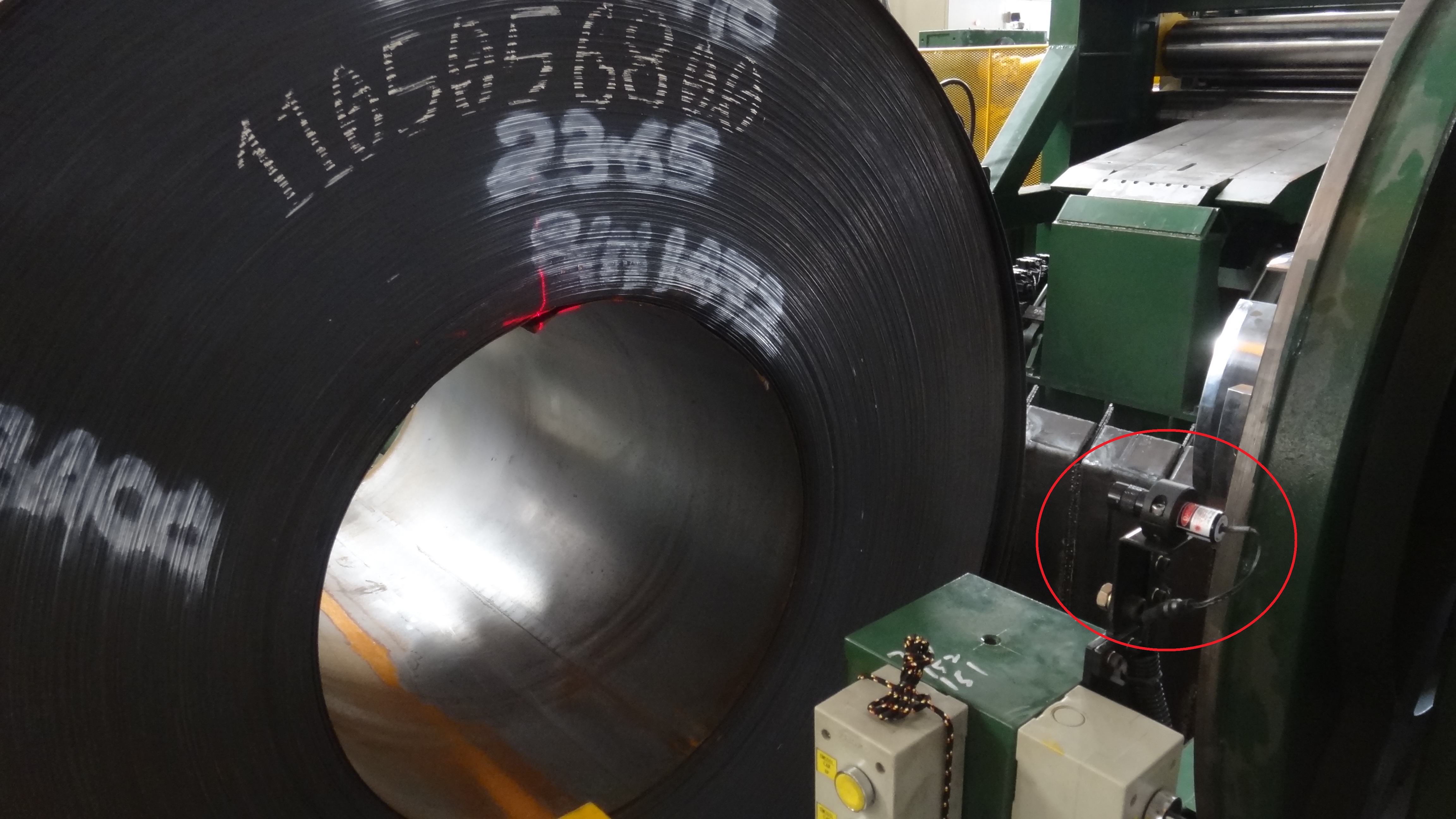

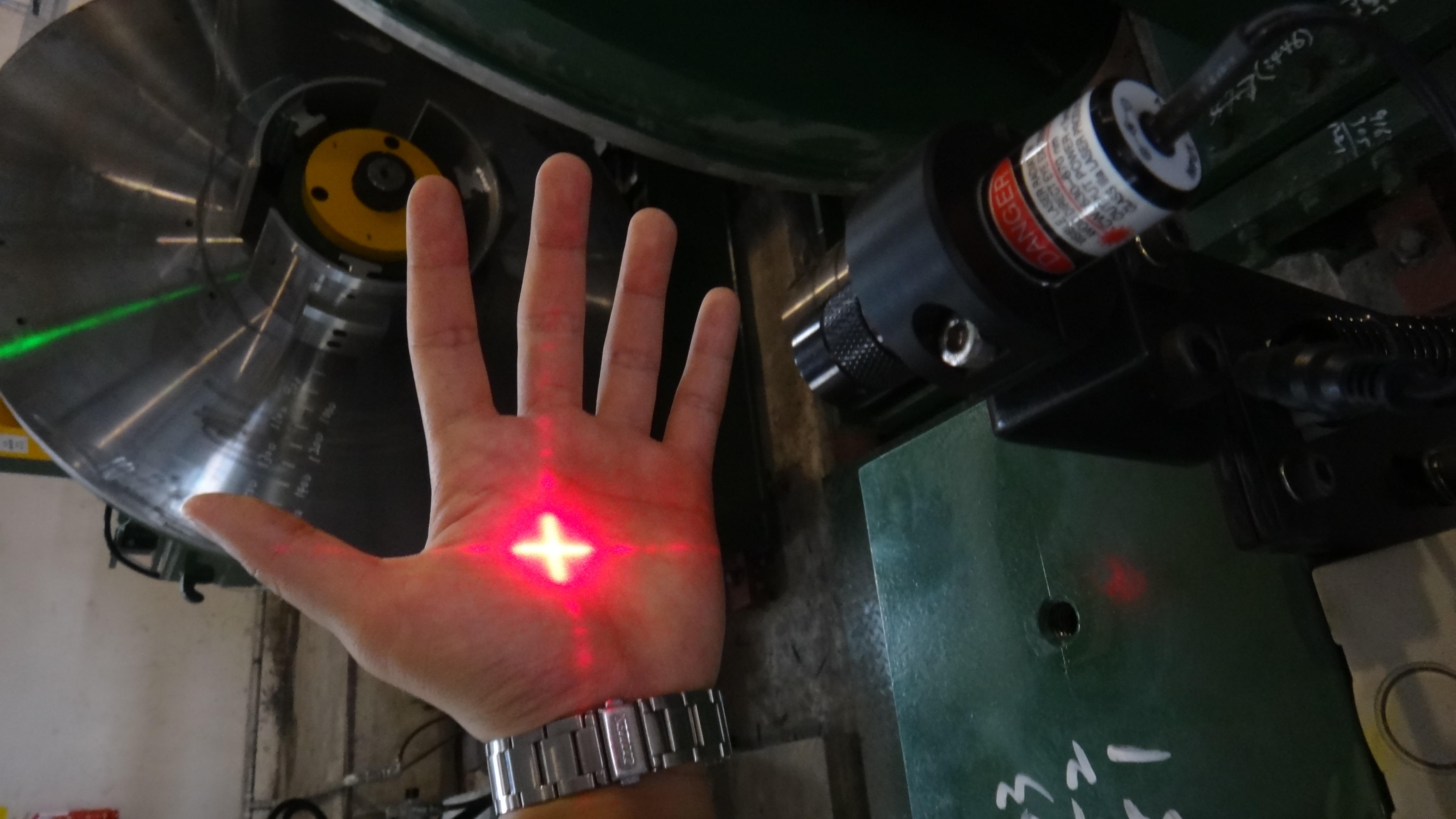

* Laser guide for coil to load on uncoiler

1. Laser beams mark the accurate coil height and edge position for coil car to adjust. Operator can follow the beam guidance easily and quickly to load coil accurately on uncoiler.

*Laminator for paper or film

1. Laminator includes a material support shaft, drum heater, and spread roll.

2. material support shaft is with inflatable core to hold paper roll or film roll quickly.

3. The drum heater can help to dry the paper so that the static electricity can stay longer to adhesive paper on coil material.

4. Spread roll can go up/down to spread paper or PVC film even on coil material.

*Side trimmer

1. Round knives positions are easily and quickly set-up on side trimmer shaft which is with pneumatic or hydraulic inflatable core to fix position in 5 seconds.

*Off-line scrap winder – Tension free

1. Off-line scrap winder won’t interrupt machine line operation because of scrap strip breakage caused by coil width variation.

2. To wind up for disposal can be done any time at operator’s free time. No machine downtime.

*On-line scrap winder speed & torque auto adjusted

1. Servo-motor-controlled scrap winder can auto adjust torque and speed for different coil thickness and width.

2. Installed on machine, no land space occupied

*Paper rewinder

1. Paper rewinder is to recycle the paper interleaf for the coil of stainless steel.

2. The recycled paper shall be rewound as a tight paper roll for disposal.